Communicating for a Smarter Factory

It is a known fact that knowledge is power in today’s business world. In the manufacturing industry, sharing the right information at the right time between all related departments is critical to ensure smooth operations of a factory.

Transitioning into a Smart Factory requires not only smooth communication between departments but also good management of customer and supplier information, as well as integrated data communication for improved warehousing and production operation. It may seem daunting for the uninitiated as there are many systems that need to talk to each other, and this can be a problem as unintegrated systems do not usually play nice with each other.

We have identified six major areas that need to communicate smoothly with each other for your factory to transition into a Smart Factory. Let us discuss these six areas in detail below.

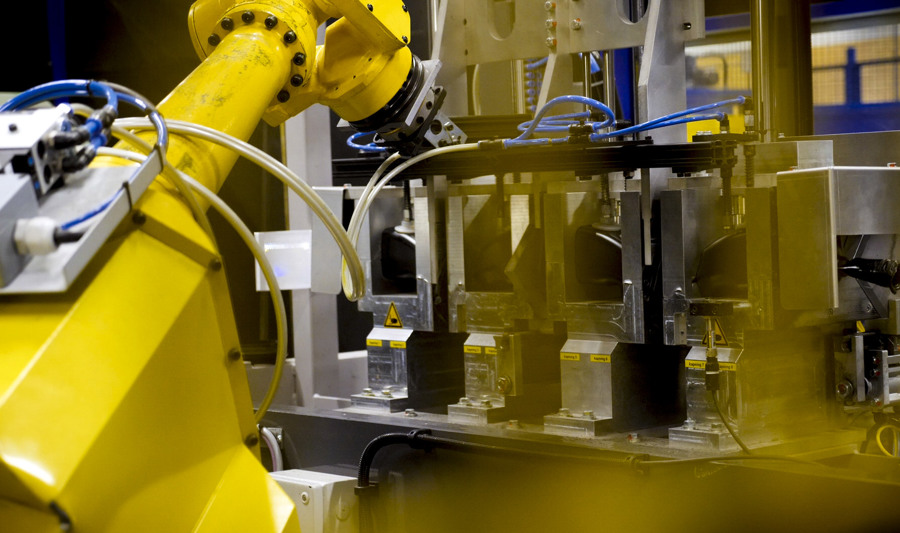

Manufacturing

At the heart of the Smart Factory is its core activity – Manufacturing. The manufacturing process involves many other activities such as BOM and routing, pre-calculations, registering manufacturing orders, etc.

Smooth communication of information is required for production planning, and process coordination to be done. A fully integrated ERP system will provide all the necessary tools needed to digitize your production flow and make sure information is communicated consistently to all related departments on time.

Purchase

The purchasing process may seem simple up front but gets complicated to manage quickly as your supplier list and orders start to grow. Supplier Relationship Management (SRM) is an important functionality for Smart Factories.

Being able to manage massive lists of suppliers, invoices, purchase orders and follow up on purchase statistics, supplier rating and order backlogs efficiently is key to ensuring your production lines do not run out of raw materials mid cycle.

By digitizing all data and documents in the purchase process, you can communicate correct information consistently to all relevant parties quickly. This cuts down on human errors compared to manual processes where anything from missing documents to sharing incorrect information may happen.

Sales

This is perhaps the most interesting and important process in your manufacturing business as it is the process of bringing in revenue.

Like the purchase process above, there are customer lists and various documents such as quotations, invoices, customer orders, etc. to manage. Managing all this information manually can be a recipe for disaster in the long run as not everyone may receive accurate information consistently.

Receiving incorrect information can be detrimental as it could cause delivery dates to be missed, invoices left unpaid and cash flows to be incorrectly forecasted.

By digitizing all sales data, you can be sure that the information communicated to all relevant personnel will be timely and accurate. This can lead to higher profits as you start to hit delivery dates consistently and respond to customer orders quickly and accurately.

Stock Module

Keeping track of your stock is not as easy as it sounds, especially when you have a long inventory list and only a handful of people in the warehouse who are familiar with all the data.

What this basically means is that the reliability of requirements and production planning depends on the accuracy of information communicated by your warehouse personnel. There is also the risk of miscalculated stock balances that could affect production planning negatively.

A smart digital system ensures accurate inventory data is kept and communicated for better planning and decision making. If well implemented, it also allows traceability for each item in your stock.

Time Recording

Taking attendance, recording work performance are vital in production planning and some critical decision making. If attendance is not taken properly and some production staff are absent, you would not be able to meticulously plan production activities for the day.

If attendance and work performance information were captured digitally and communicated in a timely manner, then you can easily assign the right production staff to temporarily fill the place of an absentee.

Attendance records are also critical information for salaries to be calculated as well as work to be scheduled. Digitizing all this data makes it easy to communicate it to the relevant departments and it will also make their work run smoother and more efficiently.

Accounting

Keeping the books right is essential for any successful business. However, handling multiple accounts, recording transactions, and generating financial reports is not to be sneezed at. There is a lot of data to be managed and one innocent error can cause major errors in your accounts.

As such, having a digital system to help keep all financial data in line will make accounting processes run smoothly while reducing the number of errors that may occur. A digitized system is also able to help with integrity within the company.

We have discussed the 6 major areas in a manufacturing business that stand to benefit from digitization of processes, smooth communication, and data integrity.

This may all sound overly complicated and possibly expensive to implement. It probably is a big and expensive project that requires multiple customizations if the solution is not a complete and fully integrated system.

It need not be expensive to implement such a system. Monitor offers a fully integrated system that is quick to implement and affordable at the same time.

You may also be interested in reading about the experience of Mah Sing Plastics Industries Sdn. Bhd. who has used Monitor ERP for over a year and believes that we are a good partner to help them get one step closer to becoming a Smart Factory.