Harju Elekter replaces several different systems with Monitor ERP

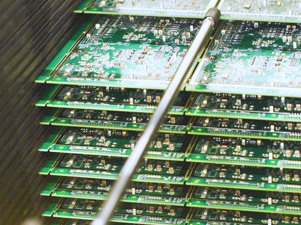

Harju Elekter, part of the Harju Elekter group, manufacture electrical equipment and energy transfer solutions. By using Monitor ERP, the company is able to manage their business, calculate their carbon footprint, and integrate processes. A major driving factor behind the integration was the desire to have everything they need on a single platform – replacing several different systems with “one icon on the desktop.”

“The biggest benefit of Monitor ERP is that the system is developed with the manufacturing industry in mind and is constantly being improved. I have experience from previous companies where we implemented Monitor ERP and achieved 20% growth, which clearly shows how you can grow when you have a good and efficient ERP system where everything is integrated,” says Alvar Sass, Managing Director at Harju Elekter.

The biggest benefit of Monitor ERP is that the system is developed with the manufacturing industry in mind and is constantly being improved.

Monitor ERP manages customer relationships, price suggestions, project administration, production planning, post-calculations, and machine integration which creates a complete workflow all within one system. This has reduced Harju Elekter’s downtime, simplified the running of the factory, and ensured that all departments can easily access data.

With increased transparency, notable improvements to efficiency, and a smoother integration of processes, Harju Elekter sees Monitor ERP as a key factor in their competitiveness. The company continues to use the system to help them make decisions as well as manage their production and customers, while ensuring that all data needed to run the factory can be found in the one system.